FREQUENTLY ASKED QUESTIONS

IF YOUR QUESTION ISN’T HERE, CONTACT US RIGHT AWAY. HAPPY TO TALK WITH YOU.

QUESTION - Is the 3rd Axle constantly working in a 6×6 AUSTRALIA system?

ANSWER - Yes, the Drive to its Rearmost Diff works “On Demand”. Our system operates in full-time bogie-drive, providing dependable user-friendly operation.

This makes our 6×6 the ultimate in safe carriage of Payloads and Towing any kind of Heavy Trailer, especially when called for in the wet or on other slippery surfaces, for example ‘Black Ice’ on Alpine Roads during Winter.

Your 6×6 vehicle with our advanced Load-sharing/Roll-steering system technology becomes practically “planted” to the road surface, and is the new paradigm in Tow vehicle safety.

QUESTION - Compared with a standard 4×4, do the rear tyres on your 6×6 conversion wear faster than normal ?

ANSWER - This is a valid question. Most 6×6 conversion systems suffer ‘Tyre Scrubbing’. A condition where the Rearmost Wheel set is effectively dragged around tight turns.

With bulk traction of the 4 rear wheels under power, and so close together, the answer is yes, for most 6×6 systems anyway… But not ours!

With our conversions, we have no noticeable increase in tyre wear over time.

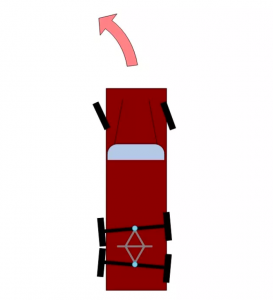

We’re confident this benefit comes from the ‘Roll-steer’ function our design boasts. As the weight is forced outwardly around a corner (Centrifugal Force and Body Roll), our Suspension subtly steers the Bogie in support of the Front Steer Axle.

The outer two wheels of the Bogie set will spread apart slightly, and the inner two wheels will contract toward each other. This effectively steers it like how a Skateboard does.

6×6 AUSTRALIA’S suspension system is the only one in the world you’ll honestly find has integrated ‘Roll-steering’.

Ours alleviates the rear tyre wear while other suppliers of 6×6 can’t provide this, as it’s normally unavoidable when you have such extreme traction with 4 ‘drive-wheels’ so close together under your vehicle.

The fact ours is most easy to use, to maintain, and that it’s daily maintenance costs are lower than others (not to mention our purchase price being so much lower), as well as outperforming any competition gives ours the edge over all comers.

As long you take care of your tyres, regularly rotating them and monitoring their pressures, rear tyre wear doesn’t noticeably increase with a 6×6 AUSTRALIA conversion.

QUESTION - Can a 6X6 conversion be driven with a standard car licence?

ANSWER - Yes, our 6X6 can be driven on a standard car licence.

You still need to drive it a little like you’re driving a small truck though.

Because it is just that, a kind of small semi-trailer. It is capable of carrying more weight, and towing much larger trailers than usual.

Our common conversions usually come in Middleweight configuration (4,495kg GVM & 7,995kg GCM).

We also do various Heavyweight models. These conversions require a heavy vehicle licence to operate (upwards of 5,500kg GVM and more than 8,500kg GCM).

QUESTION - Explain “LOADSHARE” to us?

ANSWER - “Loadshare” is the ability of the Bogie-drive (twin Rear Axles) to work together as a team of four Wheels.

With our system, as opposed to all our competitors, our Bogie-drive Axles are connected through the Suspension’s Loadshare Beams (with Coil Springs), Lower-control Rods, and A-Arms.

These components allow each Axle to sense when its fellow Axles are maneuvering or losing traction at all (e.g. over an obstacle).

So the complementary Axle manipulates its Wheels into an optimal position. This means they share the load of the Chassis & Payload weight above them effectively, spreading the force applied by that “Sprung Weight” down through their Wheels into the Road/Track surface.

Every single one of our competitor’s systems are grossly ineffective in regard to this important engineering aspect of Bogie-drive (6×6) systems design.

Ask further about the concept of ‘LOADSHARE’ when you inquire with us, and we’ll provide you with more clear understanding on the difference between a ‘6×6 AUSTRALIA’ Bogie-drive system, and any other that dares to compete with us.

When each Axle in a Bogie-drive system doesn’t know what their buddy Axle is doing, they think they’re alone and so they slip and tramp and behave uncontrollably in an effort to handle the Sprung Weight Load. Ours work in seamless partnership with one other to hold solid and safe traction throughout any and every scenario by sharing the load effectively.

QUESTION- What extension length does it give to the tray?

ANSWER - This depends what you purpose your 6×6 for.

We extend the Chassis by a minimum of 1,000mm to fit our Bogie-drive Suspensions, which allows same for a new tray.

Depending on its purpose, any reasonable length (up to 1,800mm extension) can be added to the Chassis and Tray Bodies.

QUESTION - What are your Warranty Terms/Coverage?

ANSWER - General terms of warranty on our 6×6 conversions are:

-Standard Warranty is for 2month/20,000km from date of completion;

-Standard Warranty covers full Repairs &/or Replacement on any possible faulty Workmanship, or Components that occur within the period set out above;

-These repairs/replacement works are only completed at the 6X6 AUSTRALIA Pty Ltd company headquarters in Coraki, NSW on our ‘Back to Base’ protocol;

QUESTION - Who does all your custom Bodywork and Spray-painting?

ANSWER - We handle all custom Bodywork and paint refinishing in-house.

With our custom Panel-beating and Bodywork experts on staff, we’re capable of working with you and your imagination to find exactly what you require.

QUESTION - Does 6X6 AUSTRALIA do any other optional custom extras, like Long-range Fuel Tanks, Toolboxes, Canopies, Water Tanks, Diff Lockers, or Front End Suspension Lifts, etc?

ANSWER - Yes. We do some different types of custom aftermarket Bodywork, including Tray-bodies, Bus Bodies, Tanks, Canopies with Drawers, Toolboxes, Bars, Diff Locks, Front-end Suspension Lifts with aftermarket Shock Absorbers all round, and custom Drive-line enhancements.

Just ask if there’s something you’d like, even if it isn’t listed here.

QUESTION- Why is everyone who Tows or carries substantial weight buying a 6×6 conversion?

ANSWER - The main reason is SAFETY above and beyond your vehicle’s original “Registered safe capabilities”.

The article below independently explains this.

(click on this link: https://practicalmotoring.com.au/car-advice/why-a-3500kg-tow-rating-may-not-really-be-a-3500kg-tow-rating/) for independent information on Tow-ratings re: Vehicle GVM/GCM, the Laws around this, and Real World Safety relating to Towing Trailers (and the benefits of our 6×6).

6x6 AUSTRALIA Bogie-drive conversions offer real safety and ease-of-use in Heavy Towing, Payload Carriage, and in general Off-road or Bush/Outback pursuits.

They can now carry loads more, go faraway on exploration adventures, and make it there and then return in one piece to tell of the adventure.

With our 6X6, make it easier to carry and tow more in safety and comfort.

For independent viewpoint on why more people are opting for a ‘6×6 AUSTRALIA’ conversion, read this ‘Practical Motoring’ online magazine article, focusing on one of the most affordable options of all our different conversions, the Mazda BT50 6×6:

(Link: https://practicalmotoring.com.au/car-reviews/6×6-australia-mazda-bt-50-review-beats-4×4/)

There’s no comparison on the global 6×6 conversion market. With our ‘Roller-drive’ Power-divider (Registered Design) we have become industry leaders in Automotive Drive-line technologies.

This device has found work in the famous ‘Zamboni’ ice-resurfacing machine, a tractor of sorts used in nearly every indoor ice-skating rink around the world, and known for its traction (vital when working on ice).

Governing the drive force in something with such bulk traction in such a tight proximity between wheels, is the same as how it governs the intense force of drive that regulates the bogie wheels in our 6x6s, which kind of “fight each other”, due to their proximity to one another.

Our 6X6, with its constant Twin Axle Bogie-drive setup is what this phenomenally simple little invention was designed for in the beginning.

Our suspension is designed so the heavier the load, the better the ‘Roll-steer’ function works.

It uses the Payload and its natural physical forces downward into the Road/Track with Gravity and Inertia.

Using these forces to control/manipulate the Suspension to assist vehicle handling, especially at speeds of over 50km/hr, and actually increases stability there.

With fundamental ‘Applied Physics’ used beautifully throughout its design, our 6×6 Suspension and Driveline offers two complementary systems that work so well at their tasks set out before them, together they are one complex system, and seen as very highly-advanced.

Contact us to quickly discuss what we can do to help serve your needs, and invite you to come and visit us any time to get a real life demonstration.

We’ll show you what options best suit your requirements.

Then negotiate a final build price with timeline for commencement / completion with you.

Robust engineering and fabrication allows us to give the Chassis and Suspension a Lifetime Warranty on Components and Workmanship. Power-divider and Drive-line Warranty remains as is, at 12months/20,000km from date of completion.

Nothing compares to 6×6 AUSTRALIA Pty Ltd’s Bogie-drive conversions with the Heavy Duty Weight-carrying abilities, the Coil Spring Ride Comfort, the Safety Performance, the Low-maintenance Mechanicals (therefore lower costs), and with affordability and ease-of-use by direct comparison.

Full load-sharing of payload weight to each wheel, with up to 500mm wheel travel (nothing else comes even close to this. see link https://www.youtube.com/watch?v=GsdyD_gfH98).

Full load-sharing of payload weight to each wheel, with up to 500mm wheel travel (nothing else comes even close to this. see link https://www.youtube.com/watch?v=GsdyD_gfH98).

Ours outperforms all other Bogie-drive suspension systems on Earth.